Renovation and retrofit projects rarely start with a blank slate. They start with an existing building—one that has evolved over time, absorbed changes, and often drifted away from what the drawings say.

Walls move. Equipment gets replaced. Utilities are rerouted. And documentation doesn’t always keep up.

When teams begin design or construction using incomplete or outdated information, even small inaccuracies can turn into RFIs, redesigns, and rework in the field. Laser scanning helps renovation teams simplify that complexity by starting with accurate, reality-based existing conditions.

In this article, we explore:

Why renovations are harder than new construction

New construction benefits from controlled conditions and known geometry. Renovations do not.

Most retrofit, remodel, expansions, or fit-ups projects involve:

- Existing structures with undocumented modifications

- Limited access to ceilings, interstitial spaces, or mechanical rooms

- Buildings that remain occupied or operational during work

- Tight tolerances where new systems must fit into old constraints

These challenges matter because renovation decisions build on one another. A missed dimension early in design can affect fabrication, scheduling, and installation later on. The cost of fixing issues after construction starts is significantly higher than addressing them upfront.

The risk of relying on traditional field measurements

Many renovation projects still rely on manual field measurements or legacy drawings to document existing conditions. While this approach may feel familiar, it introduces risk.

Manual measurements:

- Capture only selective points, not the full environment

- Require multiple site visits as questions arise

- Are difficult to verify once teams leave the site

- Can conflict when multiple trades collect data separately

Outdated drawings compound the problem. Buildings often look very different from what’s shown on record documents, especially in facilities that have undergone years of upgrades or maintenance.

When teams don’t fully trust the existing conditions, progress slows. Designers hesitate. Contractors add contingencies. Coordination becomes reactive instead of proactive.

How laser scanning changes the starting point

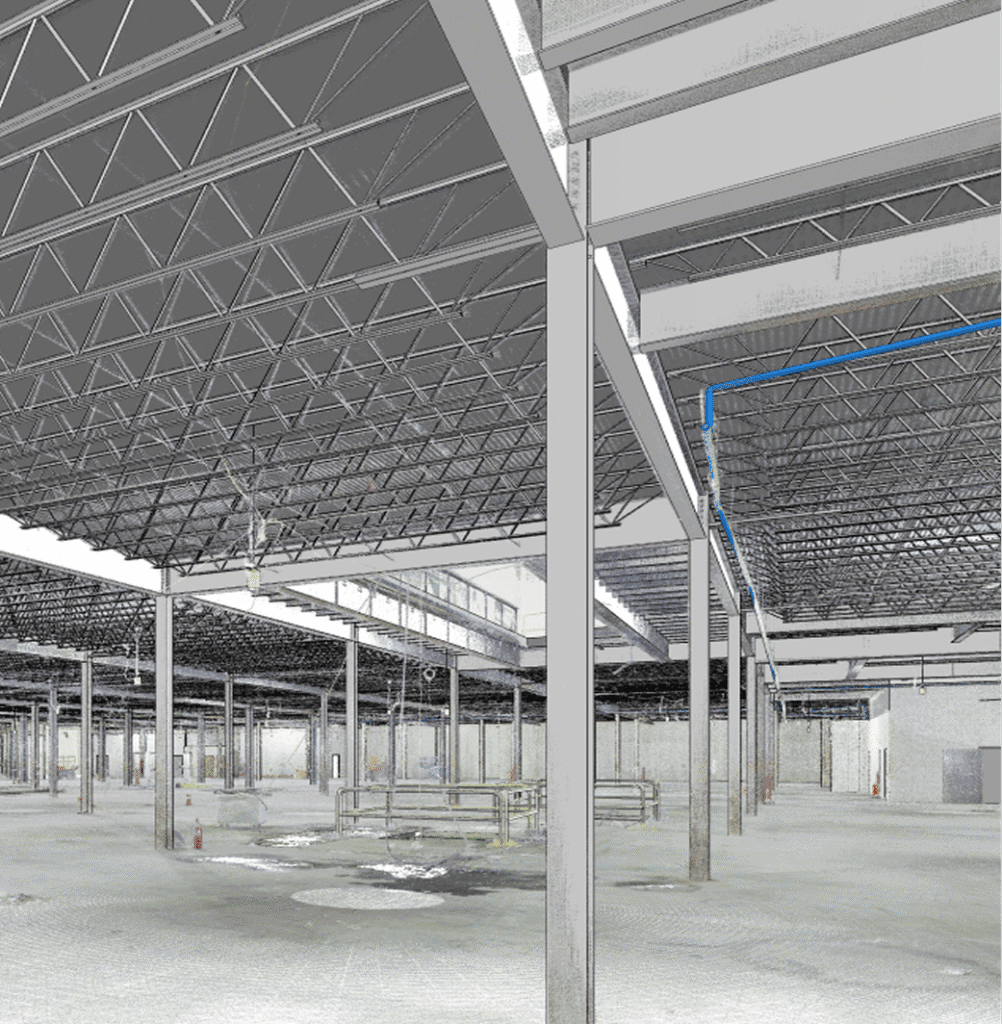

Laser scanning captures millions of precise data points across a space in a short amount of time. Instead of selective measurements, teams get a complete, objective record of what actually exists.

One way renovation teams reduce uncertainty is by using laser scanning to document the building before design and coordination begin. The scan reflects real geometry, real clearances, and real constraints—without interpretation or assumptions.

This approach provides:

- Accurate existing conditions documentation

- A single source of truth for all project stakeholders

- Fewer follow-up site visits

- Higher confidence during early planning

Laser scanning doesn’t simplify renovations by removing complexity. It simplifies them by removing guesswork.

Turning scan data into usable design tools

Scan data becomes most valuable when it’s translated into models and drawings teams can work from every day.

Laser scans are commonly converted into 3D Revit models that represent architectural, structural, and MEP elements as they exist in the field. Designers can then build directly against reality rather than abstract drawings.

Accurate models support:

- Cleaner coordination between new and existing systems

- Clash detection before construction begins

- Faster design reviews and approvals

- Reduced RFIs during construction

When everyone is working from the same verified information, coordination becomes smoother and decisions move faster.

Supporting renovations in live, occupied buildings

Many renovations happen while buildings remain in use. Commercial offices, hospitals, manufacturing plants, and campuses often can’t afford shutdowns just to collect measurements.

Laser scanning is well-suited for these environments. Data can be captured efficiently, often outside peak hours, with minimal disruption to occupants or operations.

This makes laser scanning especially valuable for:

- Phased renovations

- Active commercial and industrial facilities

- Retrofit projects with limited access windows

- Projects where safety and continuity matter

Teams get the information they need without slowing down the building itself.

Reducing rework during construction

One of the most significant benefits of laser scanning for renovations is reduced rework.

When construction teams receive accurate models and drawings based on real conditions, they’re less likely to encounter surprises in the field. Fit issues are identified earlier. Conflicts are resolved digitally instead of physically.

The downstream impact includes:

- Fewer change orders

- Less schedule disruption

- Reduced material waste

- Better alignment between trades

Save time and reduce costs by avoiding rework.

Improving collaboration across project teams

Renovation projects often involve many stakeholders—owners, architects, engineers, contractors, and specialty trades. When each group works from different assumptions, coordination suffers.

Laser scanning creates a shared foundation. Everyone sees the same conditions. Questions are answered with data instead of debate. Accountability improves because decisions are grounded in reality.

This shared understanding helps teams:

- Communicate more clearly

- Resolve issues earlier

- Maintain momentum through construction

Better information doesn’t just improve drawings—it improves collaboration.

A more predictable approach to renovations and retrofits

Renovations will always involve complexity. Existing buildings come with constraints that can’t be designed away.

Laser scanning doesn’t promise perfection. What it offers is predictability. By starting with accurate existing conditions, teams reduce uncertainty and make better decisions earlier in the project lifecycle.

That clarity supports smoother design, cleaner coordination, and more confident construction planning. It allows teams to focus on solving real problems instead of chasing missing information.

For renovation and retrofit projects, laser scanning isn’t about adding technology. It’s about creating a clearer path forward—one grounded in reality, not assumptions.

Laser scanning for renovations helps teams start with accurate existing conditions, make clearer decisions, and reduce surprises during construction.