Table of Contents

Scanning for Precision on a High-Profile Build

In Foxborough, Massachusetts, the New England Patriots introduced a cutting-edge, three-story training facility adjacent to Gillette Stadium, to be opened in spring 2026. Designed to optimize player development and recovery, the space includes enhanced training zones, hydrotherapy pools, performance labs, and immersive virtual reality rooms.

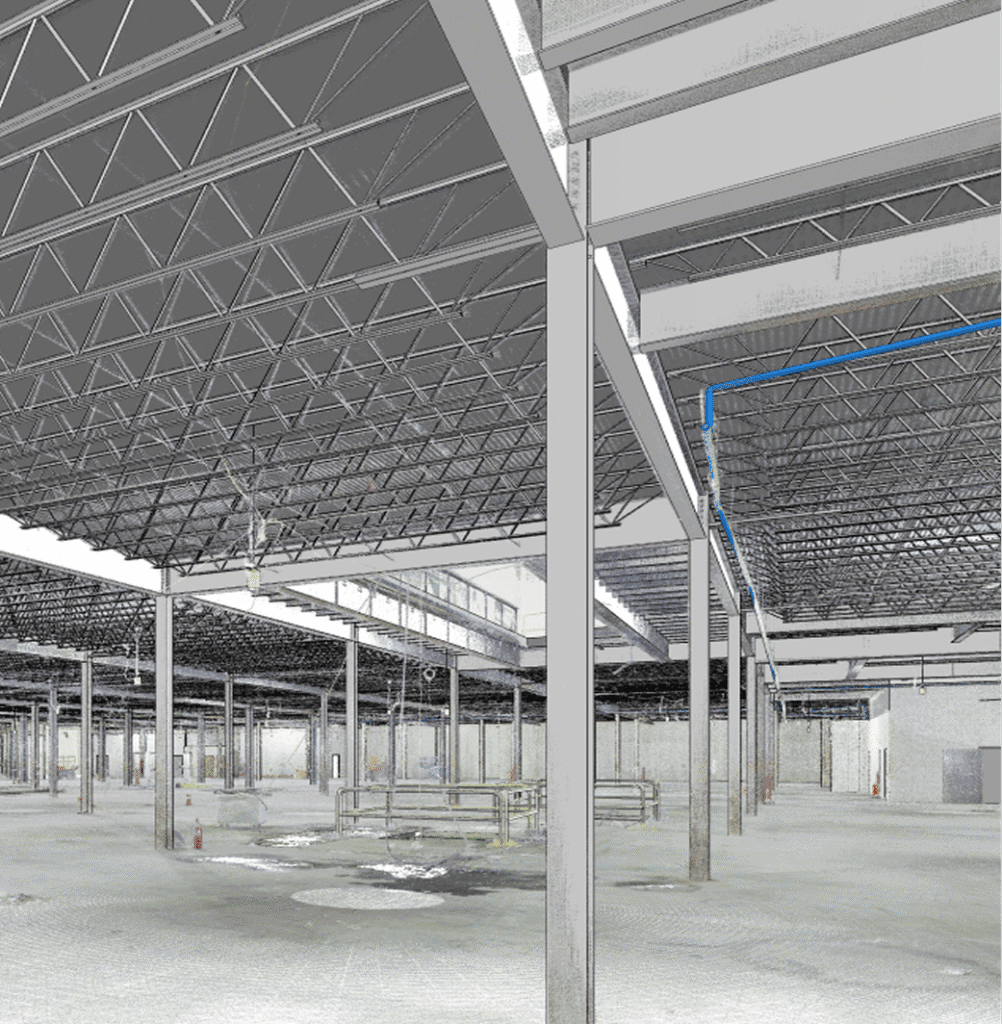

To meet the project’s exacting standards, OAR performed a full 3D laser scan of the facility’s structural steel—laying a high-accuracy foundation for the next step: a model-to-reality comparison using Leica Cyclone 3DR. This advanced software platform enabled precise digital validation of physical construction.

Leveraging Leica Cyclone 3DR for Structural Verification

OAR processed the point cloud data through Cyclone 3DR to conduct a detailed comparison between the erected steel and the IFC 3D model. The platform’s robust QA/QC capabilities and point-cloud processing tools made it ideal for early-stage verification.

By aligning field data with the design model, OAR identified deviations with millimeter-level accuracy. Cyclone 3DR’s measurement tools delivered clear, visual insights into where construction diverged from intent—giving stakeholders both precision data and accessible visualizations.

Driving Proactive Problem Solving

Following the model analysis, OAR delivered comprehensive reports identifying discrepancies between installed elements and the design. These insights empowered the construction team to resolve alignment issues before impacting downstream trades.

Benefits included:

- Early correction of structural misalignments

- Reduced schedule risk and unplanned delays

- Strengthened quality assurance with data-backed verification

These early-stage checks enabled smoother transitions to MEP and enclosure phases, supporting consistent project momentum.

Empowering Subcontractors with Actionable Insights

Beyond steel verification, Cyclone 3DR reports provided subcontractors with clear, visual deviation maps. Rather than relying solely on shop drawings or limited survey points, trades gained targeted guidance on required adjustments—enhancing both speed and accuracy in the field.

This improved:

- Interpretation of field conditions

- Onsite execution and layout precision

- Just-in-time collaboration across trades

Strengthening Project Communication

OAR’s visual reports acted as a collaborative tool across stakeholders. Heat maps and quantified deviations gave architects, engineers, contractors, and owners a shared understanding of site conditions and potential risks—even for non-technical team members.

The result: faster alignment, reduced RFIs, and more effective cross-team coordination.

Laying a Foundation for Smart Construction

While verification was just one early phase, OAR’s use of 3D scanning and Cyclone 3DR set a precedent for quality and precision. Our approach underscored the value of integrating reality capture early—mitigating risk and enabling informed decision-making at every project milestone.

As the facility progressed, OAR continued to deliver scanning insights that supported both confidence and construction accuracy, from steel erection through to finish work.

Conclusion: Anticipating Accuracy, Delivering Confidence

OAR strategic use of Leica Cyclone 3DR on the Patriots’ training facility reflects our broader commitment to precision, clarity, and innovation. Through high-fidelity laser scanning and advanced QA/QC tools, we helped build more than a facility, we helped set a new benchmark for intelligent, collaborative construction delivery.

FAQs

What is Leica Cyclone 3DR?

Cyclone 3DR is a software tool that compares 3D laser scan data to design models, identifying discrepancies and enabling precise quality control throughout construction.

Why is early structural scanning important?

Capturing steel alignment early allows teams to validate installation before other trades begin work—reducing rework and keeping schedules on track.

How were OAR’s QA/QC reports used?

The reports offered visual, data-driven insights that helped all stakeholders quickly understand alignment issues and resolve them collaboratively.