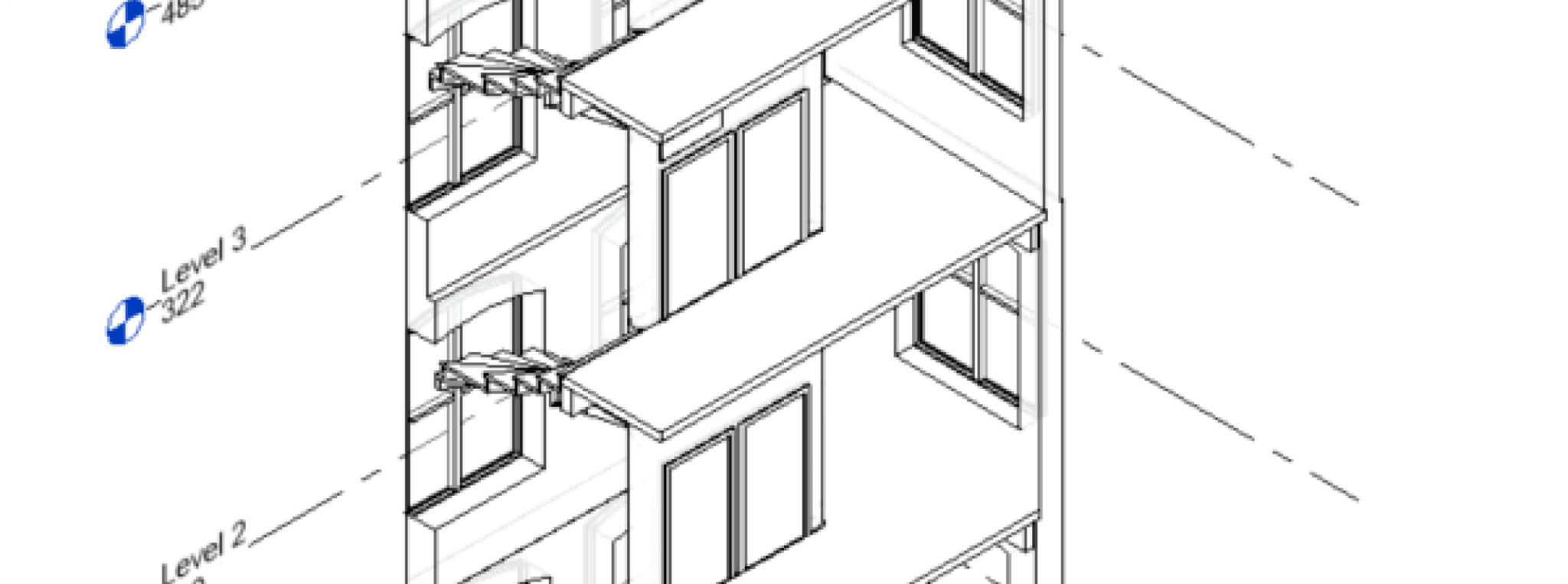

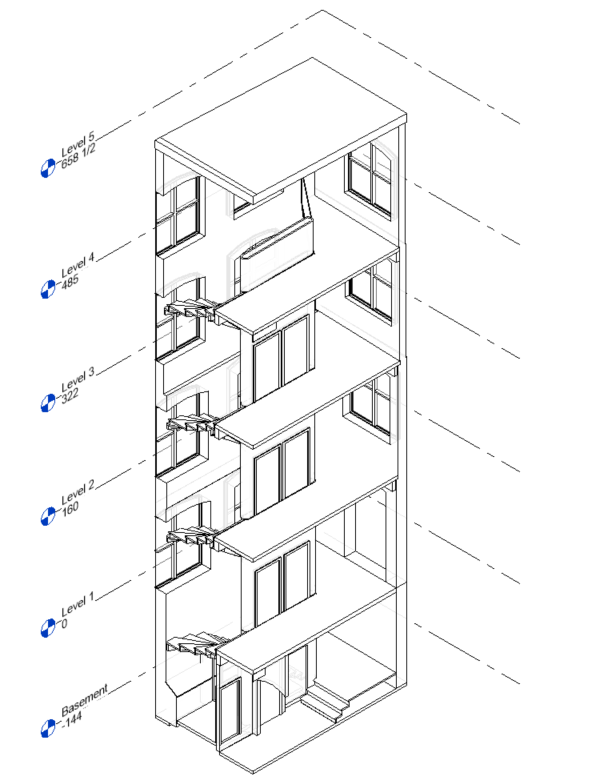

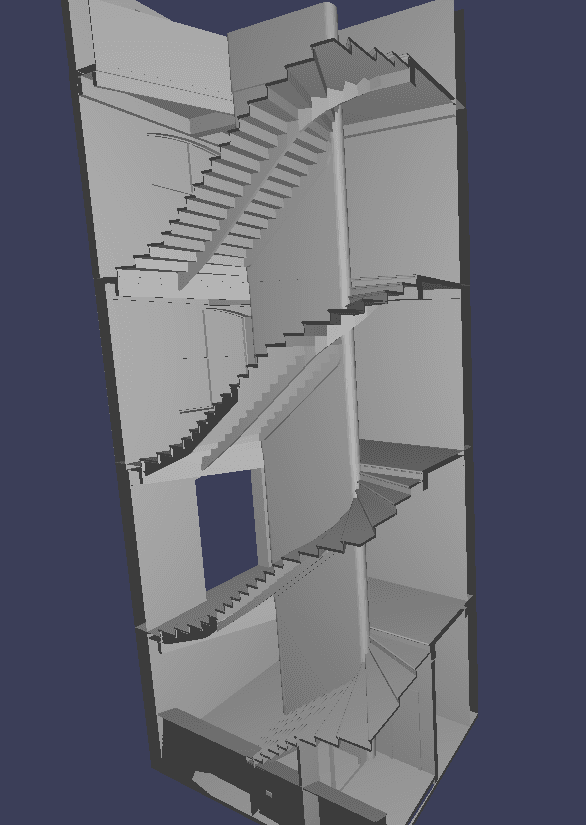

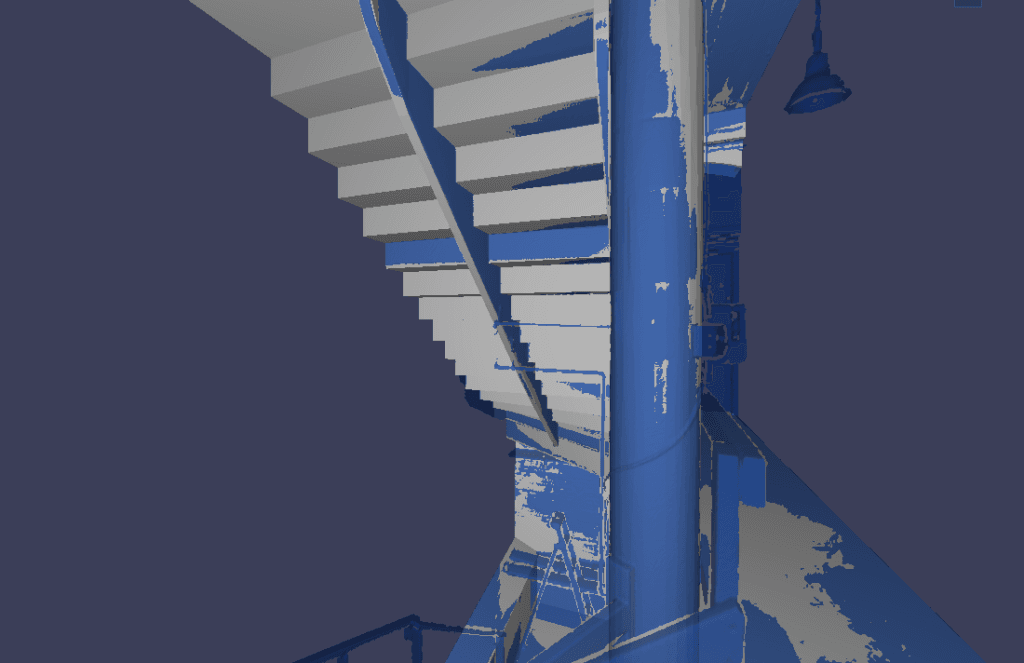

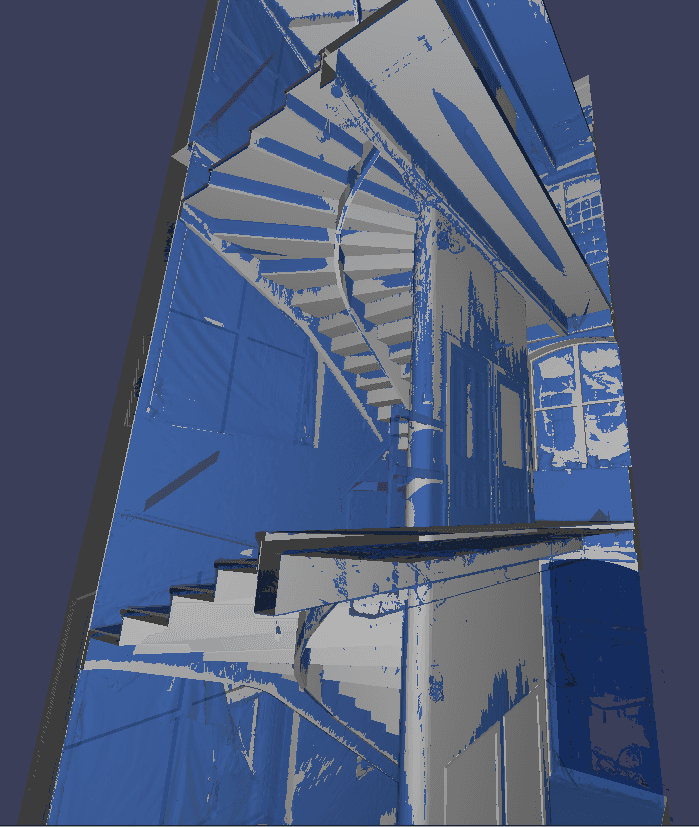

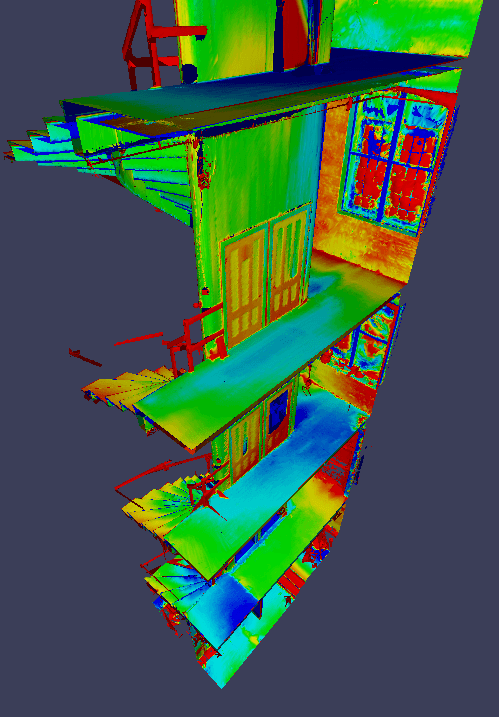

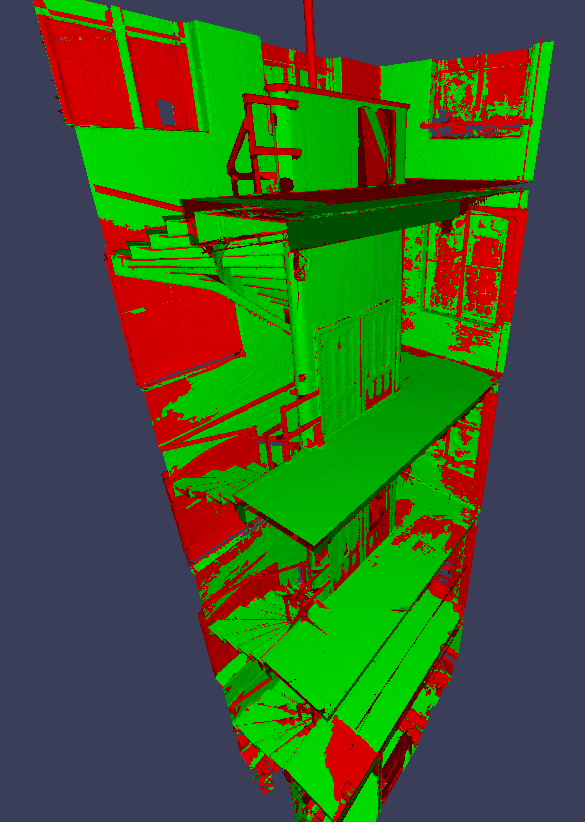

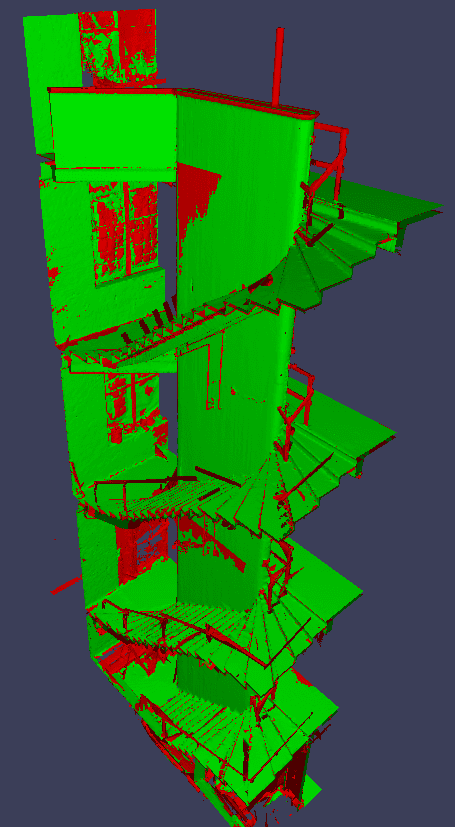

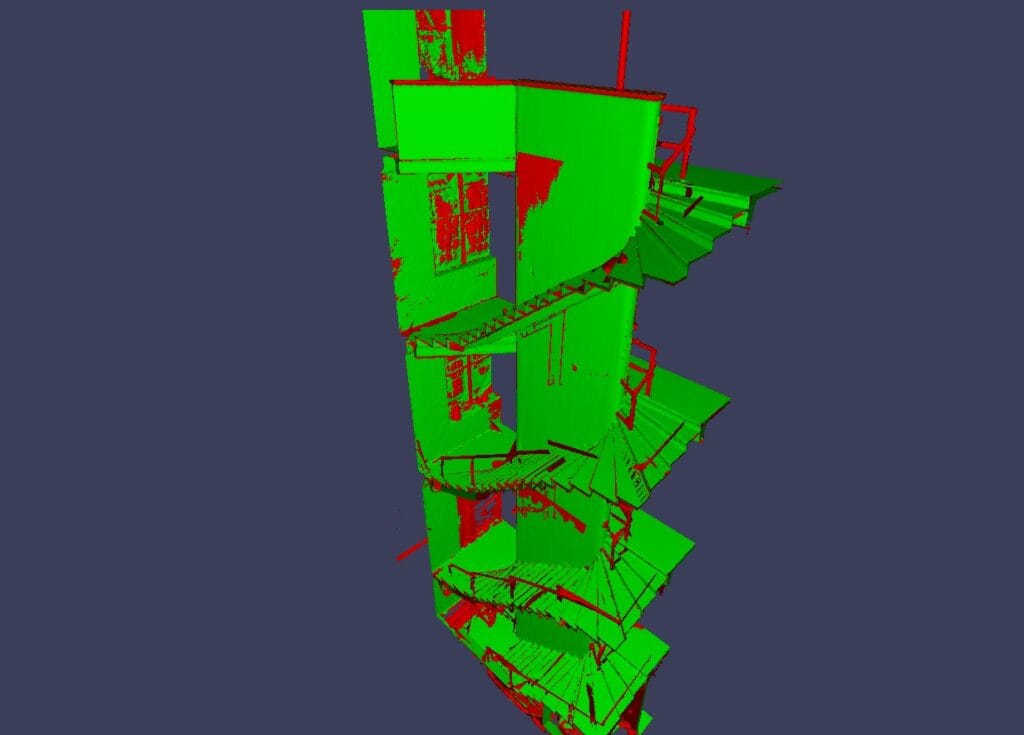

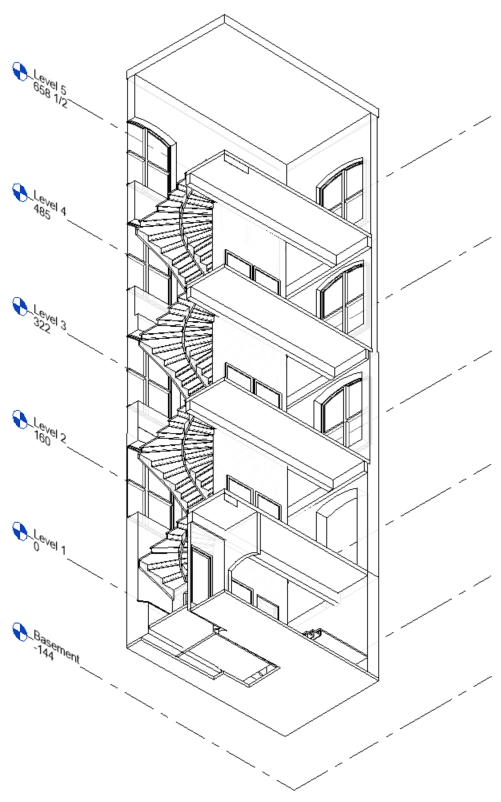

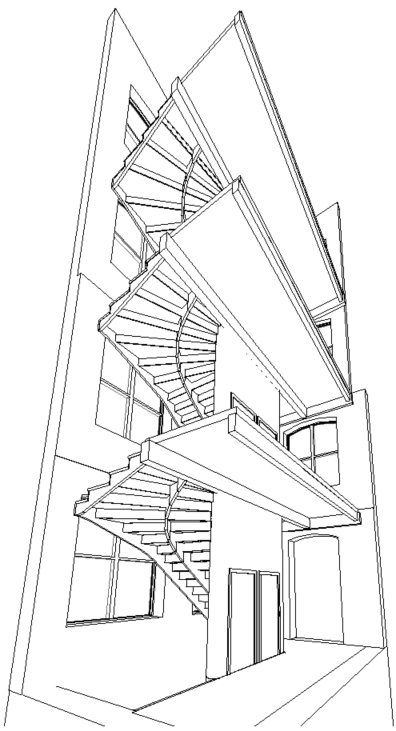

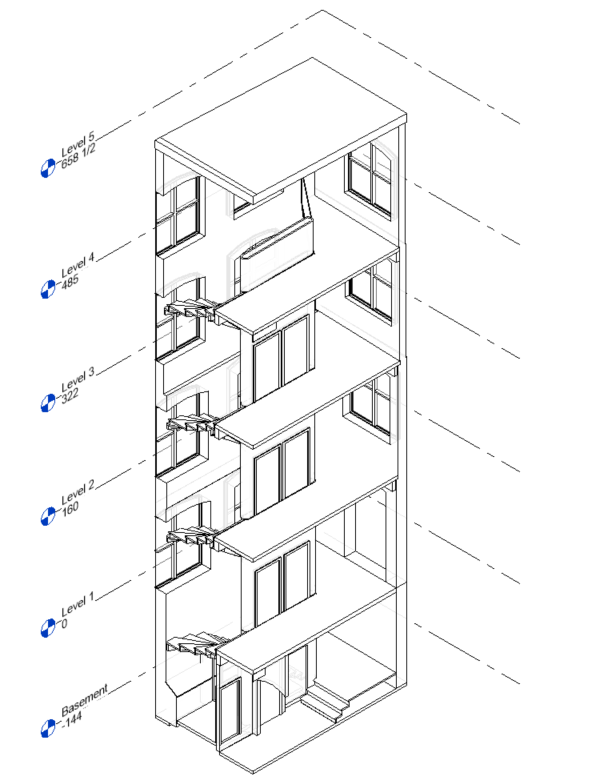

This project involved capturing and modeling two spiral staircases in a repurposed mill building being transformed into housing. The staircases’ uneven and unlevel structures presented unique challenges that required advanced scanning and tailored solutions to ensure seamless installation of prefabricated railings.

Senior Integrations Designer, Waste Management Engineering Department

OAR’s team has been great to work with throughout multiple large-scale scan to BIM projects. High attention to detail, accurate scan data, proper BIM implementation and consistent communication/support from OAR has helped to improve our project quality and efficiency from start to finish.

I hired OAR to do a pre-construction scan to point cloud mesh and 2D CAD of my new building. I am glad I did… with Jon and Ryan this business goes above and beyond

Owner, TBJ Gourmet Food Manufacturing Plant

OAR attacks their projects methodically & professionally asking detailed questions regarding our final needs to fabricate. End result was a spectacular fit of formed powder coated aluminum angle under our cable guardrail system. Can’t wait to work with OAR on the next project!

President, Multi-Weld Services INC.

Ready to take the next step?

You’ve read about us, and now we’d love to hear about you. Reach out today, and let’s talk about accelerating design and construction together.