As global supply chains face increasing uncertainty—from tariff hikes and geopolitical tensions to pandemic-driven disruptions—reshoring has evolved from a strategic option to an economic necessity. Government incentives, rising overseas labor costs, and the need for tighter supply chain control are all driving companies, including those consulting with a reshoring consulting firm, to bring manufacturing and operations back to the U.S.

Yet, while reshoring may sound promising, executing it is far from simple. Business leaders often face critical questions:

- Where should we build or adapt facilities?

- How do we maintain efficiency during the move?

- What are the regulatory requirements for U.S. compliance?

That’s where a top-tier reshoring consulting firm like OAR becomes essential. With deep expertise in spatial planning, BIM (Building Information Modeling), and digital twin simulations, OAR helps businesses achieve a faster, smarter, and more cost-effective transition back to the U.S.

Why OAR is the Reshoring Consulting Firm of Choice

Choosing the right partner can mean the difference between a seamless transition and operational chaos. Here’s why OAR stands out as the go-to reshoring consulting firm:

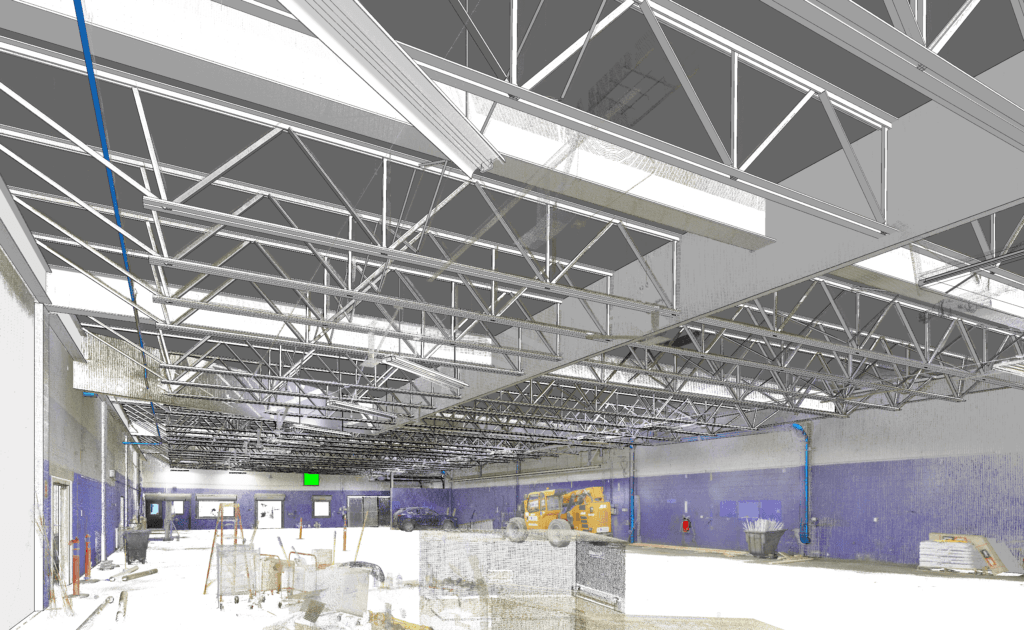

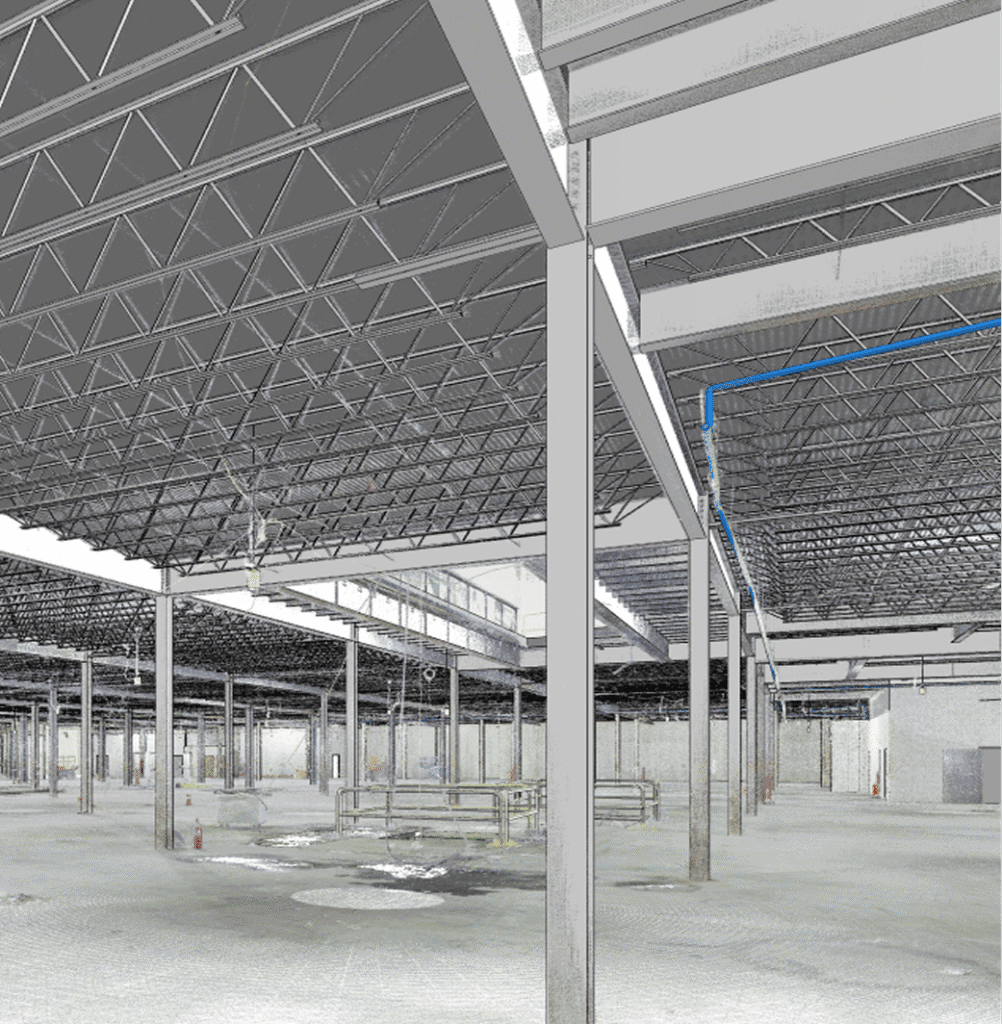

1. Precision Planning Using BIM & 3D Laser Scanning

Most facility relocations still rely on outdated manual processes, resulting in inefficiencies, missed opportunities, and costly delays. OAR eliminates these challenges through precision-driven digital planning:

✅ Accurate Site Selection: High-resolution 3D laser scanning enables meticulous site assessments and feasibility studies before you break ground.

✅ Clash Detection & 3D Coordination: BIM helps identify potential design conflicts early, allowing for preemptive corrections that avoid expensive rework.

✅ Optimized Layouts: Digital models are used to configure layouts that maximize production flow, employee movement, and equipment placement.

The result? Facilities that are engineered for performance—right from the start.

2. Cost-Effective Facility and Operational Design

Reshoring isn’t just about relocation; it’s about making your operations leaner, more agile, and more profitable in a new environment. OAR’s digital-first approach delivers measurable financial benefits:

✅ Smart Space Utilization: Reduce unused square footage and eliminate material waste with data-backed layout decisions.

✅ Lower Retrofit Costs: Virtual planning significantly reduces the time and resources needed for renovations or new builds.

✅ Optimized Production Flow: From raw material input to final product output, workflows are streamlined to reduce downtime and increase throughput.

3. Futureproof Your Operations with Digital Twins

Relocating your facilities isn’t just a one-time project—it’s a long-term strategic move. OAR leverages digital twin technology to keep your operations future-ready:

✅ Scenario Testing: Simulate alternative layouts and production scenarios before committing to changes.

✅ Performance Simulations: Identify potential bottlenecks and inefficiencies in advance.

✅ Continuous Improvement: Update your digital twin to reflect real-time data, enabling ongoing operational refinement.

This digital foresight empowers your business to adapt and scale with confidence, not guesswork.

Why Wait? Reshore Smarter with OAR Today

Reshoring isn’t just about geography—it’s about gaining a strategic advantage in the U.S. marketplace. Partnering with a premier reshoring consulting firm like OAR provides the tools, insights, and technology needed for a successful transition.

With OAR, you get:

✅ Smarter site selection and facility layout

✅ Cost-efficient, lean operational design

✅ Long-term risk mitigation and regulatory compliance

✅ Cutting-edge digital tools to futureproof your business

Ready to make reshoring seamless and profitable? Contact OAR today and begin your journey back to smarter, stronger U.S.-based operations.