Table of Contents

Installation performance is a critical part of every equipment deployment. When equipment arrives onsite, it must align with actual field conditions—bolt patterns, elevations, clearances, and supporting infrastructure. Yet many equipment suppliers still receive incomplete, outdated, or dimensionally unreliable drawings from customers.

This gap between expected conditions and actual conditions leads to delays, redesigns, and unnecessary cost exposure for both suppliers and their customers.

Once installers are onsite, any dimensional conflict becomes costly quickly. Identifying these issues before fabrication and shipping helps protect margins and accelerates commissioning.

Pre-install scanning gives equipment suppliers verified existing-conditions data early—so equipment can be engineered, fabricated, and delivered with confidence.

Why Installation Delays Blow Budgets

For equipment suppliers, installation uncertainty impacts margins in several ways:

- Field crews pause while dimensions are rechecked

- Fabricated components require rework or complete remanufacturing

- Anchor bolts, support steel, and tie-in points must be modified

- Late-stage changes disrupt customer operations

- Extra engineering, travel, and installation support erode profit

Most issues stem from relying on unverified drawings or customer-provided measurements. Without validated geometry, every deployment carries avoidable risk.

What Pre-Install Scanning Provides

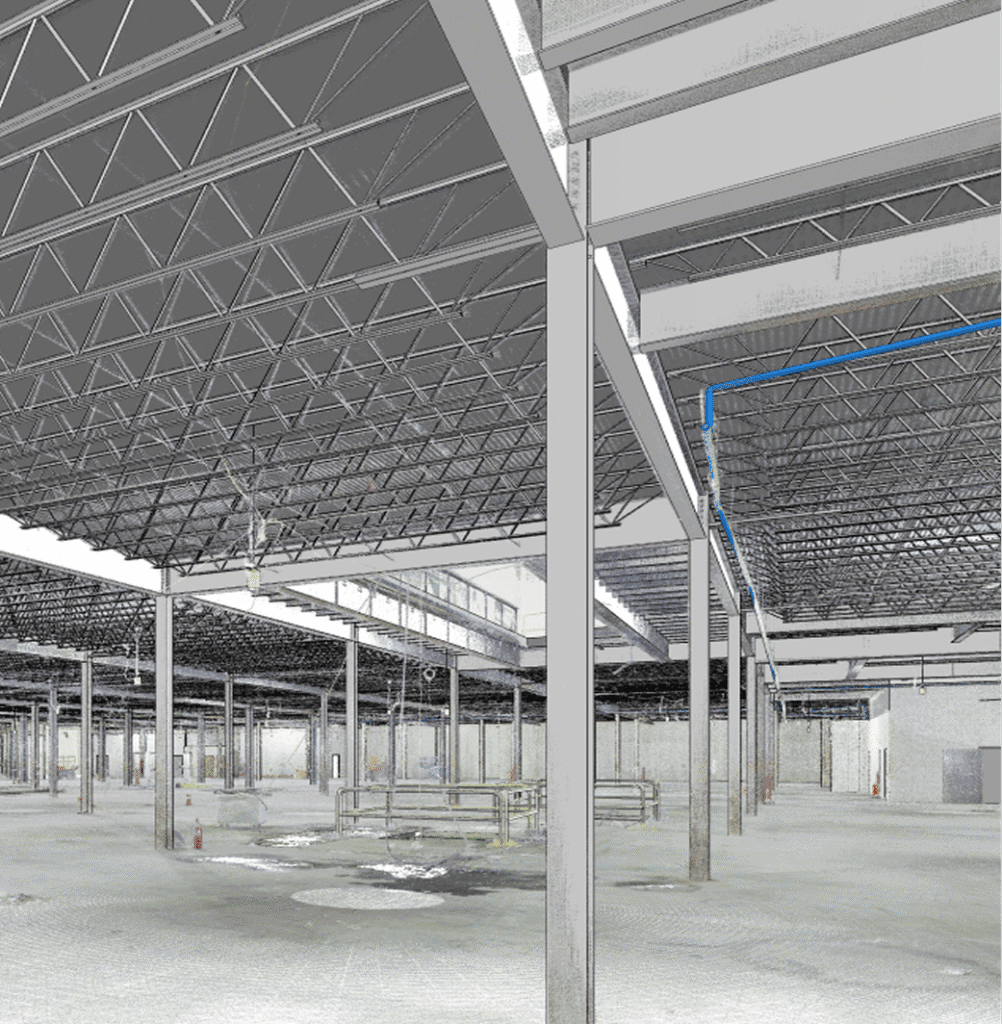

Pre-install scanning uses high-resolution LiDAR to capture the exact geometry of the installation environment. TPre-install scanning uses high-resolution LiDAR to capture the exact geometry of the installation environment. The resulting point cloud and existing-conditions 3D models become the foundation for accurate equipment design.

Scans reveal:

- Structural geometry

- Anchor bolt layouts

- Floor slopes and slab irregularities

- Mechanical and electrical tie-ins

- Tight clearances and hard-to-measure areas

Suppliers receive CAD-ready deliverables compatible with SolidWorks, Inventor, and AutoCAD, ensuring all decisions are based on verified conditions—not assumptions.

How Equipment Suppliers and Installers Use Scanning to Reduce Installation Risk

1. Validate Existing Conditions Early

Suppliers overlay their equipment models on scan geometry to check:

- Bolt patterns against real field positions

- Required clearances

- Support steel elevations

- Conflicts with MEP systems

This early comparison prevents the downstream issues that are costly to fix onsite.e.

2. Improve Design Accuracy Inside Engineering Software

Scan geometry can be delivered as STEP files, allowing suppliers to:

- Design directly against verified surfaces

- Eliminate misfits between equipment and the real site

- Improve interface coordination

When the design reflects actual conditions, fabrication accuracy increases dramatically.

3. Shorten Installation Schedules

Accurate site geometry means equipment fits the first time, reducing:

- Field adjustments

- RFI cycles

- Installation interruptions

Suppliers experience fewer support calls and faster commissioning.

4. Standardize a Reliable, Repeatable Workflow

Top equipment suppliers now integrate scanning as a standard step, helping them:

- Strengthen customer confidence

- Reduce project variability

- Improve delivery consistency

- Support multi-site deployment programs

Case Example: Using Verified Geometry to Prevent Downstream Design Issues

An equipment supplier in the baking sector was preparing to replace a large industrial oven in a legacy facility. The available drawings did not accurately represent the surrounding structure or MEP systems—an issue that could have resulted in multiple design conflicts and installation delays.

A full LiDAR scan of the oven room captured dimensions for:

- Structural elements

- Adjacent walls and slab geometry

- Mechanical and electrical lines

- Constrained areas where clearances were limited

OAR produced a parametric model from the scan and delivered it as a SolidWorks-ready STEP file, allowing the integrator to design the new oven directly in their CAD environment.

The accurate geometry revealed alignment issues that would have caused installation delays. Fixing these in the design phase protected the supplier’s schedule and ensured a first-time-right installation.

The Operational Value of a Scan-First Workflow

Pre-install scanning isn’t an extra step—it’s a risk-control measure that benefits the entire deployment lifecycle:

- More accurate design inputs

- Improved fabrication precision

- Fewer RFIs and onsite corrections

- Shorter installation durations

- Reduced burden on support teams

- Predictable project outcomes

For equipment suppliers, the return on accuracy is substantial.

Conclusion

Pre-install scanning gives equipment suppliers a dependable foundation for design, fabrication, and installation. By replacing assumptions with verified site data, suppliers reduce risk, improve installation quality, and protect margins.

High-resolution LiDAR scanning

SolidWorks-ready models

Fabrication-grade geometry

If you need verified existing conditions before your next equipment deployment, we can help.

FAQs

What is pre-install scanning for equipment suppliers?

A LiDAR-based method for capturing accurate site geometry before fabrication, ensuring equipment fits correctly the first time.

Why does pre-install scanning reduce installation delays?

It identifies clearance issues, bolt conflicts, and elevation mismatches before equipment is built.

Can scan data be used directly in engineering software like SolidWorks?

Yes — OAR converts scans to STEP files for use in SolidWorks, Inventor, or AutoCAD.

What types of equipment benefit from pre-install scanning?

Conveyors, ovens, robotics, automation cells, packaging systems, balers, and any system requiring precise placement.

How accurate is LiDAR scanning for industrial installations?

Modern LiDAR delivers millimeter-level accuracy, far surpassing manual measurement or legacy as-builts.