Table of Contents

Paper plans and flat CAD files disconnect teams from the reality of the built environment. The result? Mismatched conditions, missed details, and costly rework. When designs are built on outdated information, every step of the process becomes vulnerable to error.

Every outdated drawing introduces risk. Every site revisit adds cost. Every misalignment delays delivery. Engineering teams working with incomplete data lose time, accuracy, and competitive advantage.

That’s when reality capture comes in.

If you’re new to OAR, you can learn more about our team here.

The Limits of Traditional 2D Workflows

Traditional 2D documentation was never designed for today’s complex, systems-heavy engineering projects. Plans become outdated the moment construction begins. Field changes go unrecorded. Coordination relies on assumptions rather than verified conditions.

2D workflows limit:

- Field-to-model accuracy

- Visibility into dense MEP systems

- Clash detection and constructability

- Speed of coordination

- The ability to validate work before fabrication

These limitations create disconnects that 3D laser scanning directly solves.

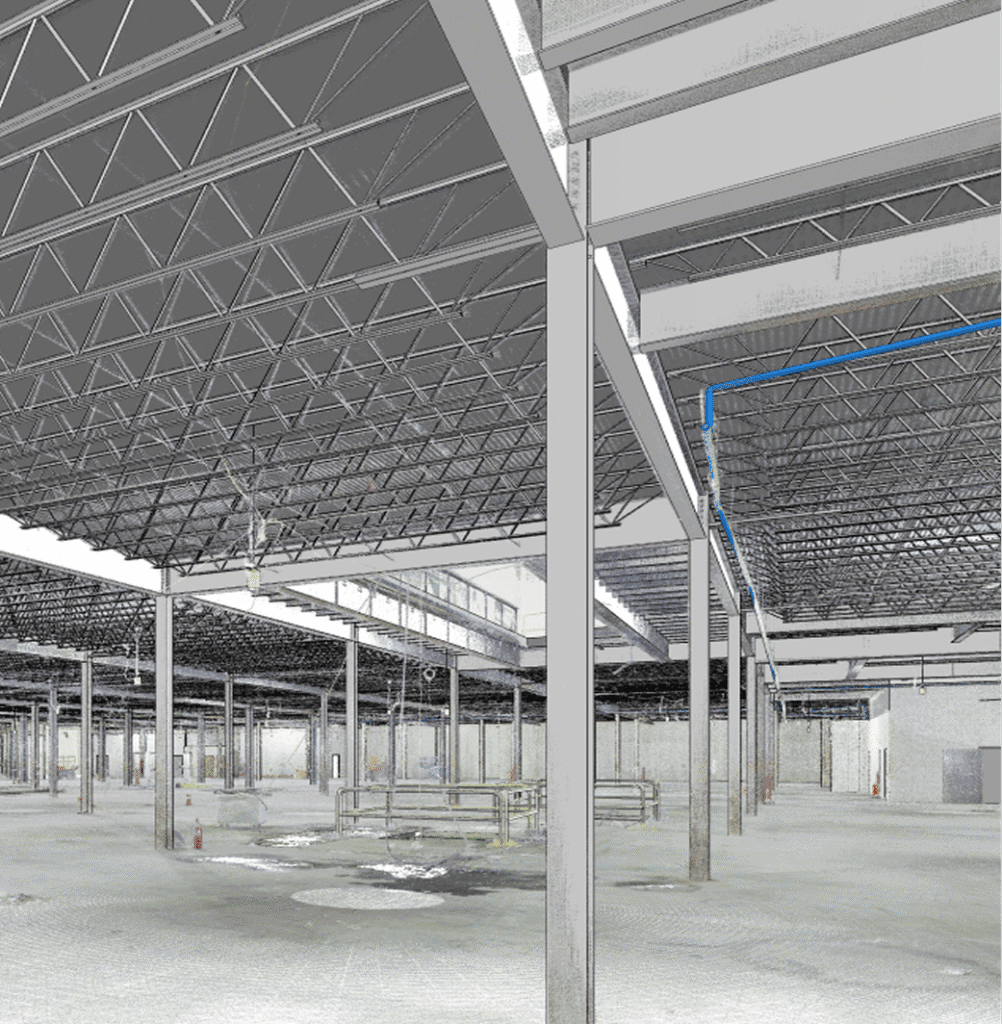

A Standard for Engineering Precision

OAR delivers high-resolution 3D laser scanning and drone-based reality capture that replaces guesswork with certainty. Our point cloud data and scan-to-BIM workflows provide teams a way to design and coordinate against actual field conditions, not assumptions.

This isn’t about flashy tech. It’s about competitive advantage: fewer RFIs, fewer change orders, faster project cycles, and more confident decisions from day one. Reality capture bridges the gap between the field and the office, creating a continuous flow of accurate information.

You can explore some of our past work on our here.

From Capture to Coordination: The OAR Advantage

We don’t just hand you a point cloud and walk away. Our team integrates reality capture directly into your engineering and BIM workflows, ensuring the data supports real project outcomes.

Our Deliverables Include:

- Scan-to-BIM conversion for Revit and other modeling tools

- As-built verification that ensures field and model alignment

- MEP coordination that reduces clashes and fabrication waste

- Digital twin readiness for long-term asset management

The outcome? Reduced risk. Accelerated timelines. Better stakeholder alignment. When your team builds from accurate data, every phase of the project improves.

Where 2D Fails, 3D Laser Scanning Leads

Retrofits & Expansions

When legacy plans are incomplete or unreliable, reality capture creates a high-fidelity digital foundation for design.

MEP-Rich Projects

For systems-heavy projects, we eliminate conflicts early, before they cost time and money onsite.

Infrastructure & Industrial Assets

Large-scale or complex environments benefit from a comprehensive 3D context that traditional surveying methods cannot fully capture.

Competitive Bids

Firms that bring OAR’s 3D data to the table win with precision, speed, and insights that competitors can’t match.

For more details on our services, visit our Services page.

Implementation Backed by Expertise

We deliver a full solution. From initial capture to model delivery, our team manages every step with technical rigor:

- Technology selection tailored to your site and scope

- Field teams trained in safe, rapid capture

- Virtual coordination specialists delivering clash-ready models

- Scalable data strategies that integrate with your existing platforms

Our holistic approach ensures reality capture is both accurate and actionable.

The Business Case for 3D Laser Scanning

3D laser scanning provides a complete digital record of existing conditions with unmatched accuracy. Instead of relying on manual measurements or outdated drawings, teams work from verified data that improves coordination, reduces field conflicts, and shortens project timelines.

Whether you’re planning a retrofit, validating installations, or coordinating dense MEP systems, laser scanning offers clarity that traditional methods cannot match.

Why Delay Is Risk

Waiting to adopt reality capture is not a neutral choice. It adds:

- More uncertainty

- More rework

- Longer schedules

- Weaker proposals

- Higher overall project risk

Modern engineering demands data-driven decision-making. 3D laser scanning provides the accuracy needed to deliver projects efficiently and competitively.

Future-Proof Engineering Starts Here

OAR is helping engineering firms across the country shift from static drawings to dynamic, data-rich models. We bring the field into your workflow with speed, precision, and purpose. Reality capture empowers your team with information that minimizes risk and maximizes clarity.

Contact OAR today to schedule a discovery call. Let’s turn uncertainty into accuracy — and vision into execution.

FAQs

What is 3D laser scanning, and how is it different from traditional surveying?

3D laser scanning uses high-accuracy scanners to generate detailed digital models of existing conditions. Unlike traditional surveying, which provides limited data points, scanning produces a full point cloud with sub-inch accuracy.

Can smaller engineering firms afford to implement reality capture?

Absolutely. OAR offers scalable solutions so firms of any size can access high-quality scanning without investing in hardware.

How does 3D laser scanning integrate with existing BIM workflows?

OAR’s scan-to-BIM deliverables are optimized for platforms like Revit and Navisworks, ensuring seamless coordination.

Which projects benefit most?

Retrofits, MEP-dense buildings, industrial sites, and infrastructure projects with outdated documentation benefit the most.

What are the risks of not adopting laser scanning?

Teams that delay face more rework, higher costs, longer schedules, and weaker competitive positioning.