ABC TechCon 2026, hosted by Associated Builders and Contractors (ABC) – New Hampshire & Vermont, brought together contractors and project leaders facing a common reality: projects are becoming more complex, timelines are tightening, and expectations around certainty are rising.

Across conversations throughout the event, the same pressures surfaced again and again—denser scopes, less margin for error, and decisions that carry real consequences much earlier in the project lifecycle. While advanced technology is becoming more prevalent on jobsites, it’s also raising the bar for how projects are planned, coordinated, and executed.

The takeaway was consistent. Contractors aren’t looking to add more tools for the sake of it. They’re looking to reduce unknowns, gain clarity on existing conditions, and avoid coordination issues that only reveal themselves once work is already underway.

The insights below reflect what we heard most often at TechCon—and why these challenges, and the ways teams are responding to them, matter for contractors across the industry.

Table of Contents

Construction technology is everywhere—but clarity is still hard to achieve

Walking the ABC TechCon floor, one thing was clear: access to technology is no longer the limiting factor.

Scanning platforms, coordination software, layout tools, and documentation systems are widely available from capable vendors across the region. Most contractors are familiar with them. Many are already using pieces of them. Yet for a large portion of small and mid-sized contractors, those tools haven’t consistently translated into better project outcomes.

The reason isn’t a lack of interest. It’s the reality of adoption.

Modern construction technology is expensive, both in capital cost and in time. Hardware, software licenses, training, and ongoing maintenance add up quickly. More importantly, these tools require fundamental changes to how projects are planned and executed. They don’t work in isolation.

Effective use depends on multiple systems working together—reality capture, 3D modeling, coordination, layout, and project controls—along with the interoperability between them. That level of integration takes time, internal alignment, and sustained effort to get right.

For many contractors, especially small and mid-sized firms, fully rolling out a reality capture– and model-driven coordination workflow can take 18 months to three years. During that time, teams are asked to change processes, learn new tools, and maintain productivity, often without immediate return.

That’s why adoption is rarely a software problem. It’s an execution problem.

Successful implementation requires:

- A clearly defined and repeatable process

- Alignment across trades and project partners

- Consistent standards and expectations

- Accountability for data quality

- And the ability to turn information into decisions, not just models

Without that structure, technology adds activity—but not clarity. And when clarity is missing, uncertainty remains, regardless of how advanced the tools appear.

Tools don’t reduce risk. Workflows do.

One of the most common questions we heard at TechCon wasn’t about whether construction technology works. It was about execution:

“How do we actually make this work across our jobs?”

Most contractors at TechCon understand the value of reality capture, 3D coordination, and model-driven workflows. The challenge isn’t ambition. It’s orchestration.

Modern construction technology ecosystems are fragmented by design. Reality capture, modeling, coordination, layout, and project controls often live in different platforms—many of them proprietary, with varying levels of interoperability. Hardware options are equally diverse, with meaningful differences in accuracy, range, speed, and suitability for different site conditions.

Choosing the right tools is only the first step. Making them work together consistently is where complexity compounds.

Execution requires:

- Aligning multiple software platforms across internal teams and external trades

- Standardizing how data is captured, modeled, and shared

- Managing handoffs between systems without degrading accuracy

- Deciding which tools are “good enough” versus overkill for a given project

- And ensuring outputs actually inform decisions, not just generate more files

On top of that, these workflows demand new skills. Contractors are faced with a real choice: invest in upskilling existing staff, hire specialized personnel to build internal departments, or rely on external expertise to support execution. Each option carries cost, time, and organizational impact.

This is why many well-intentioned technology initiatives stall. Not because the tools don’t work—but because workflows are difficult to design, even harder to standardize, and challenging to maintain across multiple projects and teams.

Risk is reduced when workflows bridge that gap—connecting reality capture, coordination, and execution into a single, repeatable process that teams can rely on. When workflows are clear and consistent, decisions move earlier, coordination improves, and the field stops being the primary place where conflicts are resolved.

That shift—not the tools themselves—is what changes outcomes.

What we shared at TechCon: reducing risk by removing assumptions

At TechCon, OAR walked through a real project case study to show how uncertainty is introduced—and removed—before construction ever starts.

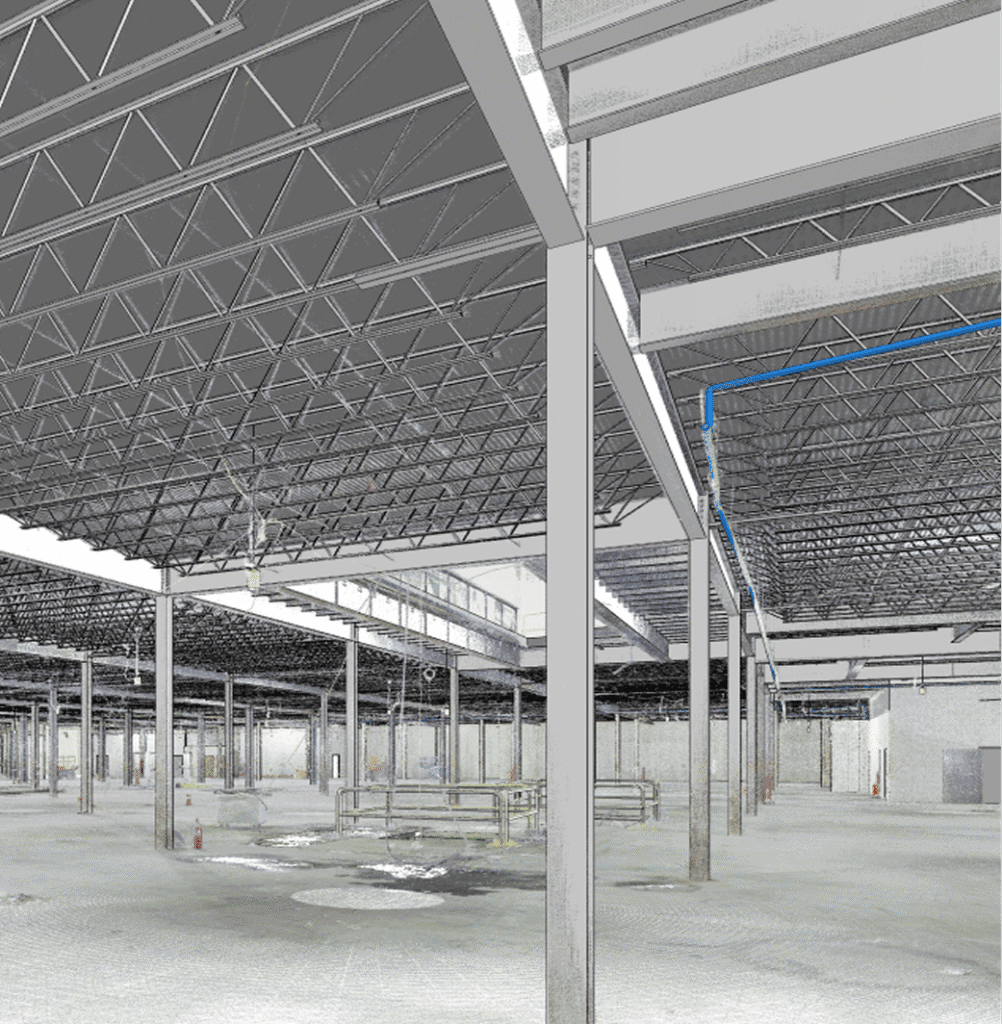

The project was a complex facility repurpose with tight spaces, outdated documentation, and multiple trades working in parallel. Like many renovation projects, early planning relied on assumptions about existing conditions that, if left unverified, would have surfaced later as RFIs, rework, and schedule pressure.

Instead of carrying those assumptions forward, the general contractor made a proactive decision to establish a clear baseline before mobilization. OAR scanned and modeled the existing conditions, creating a single source of truth that was used to drive project-wide 3D coordination and align all trades around verified reality.

The emphasis throughout the case study wasn’t on speed or sophistication. It was on decision quality.

Through virtual coordination grounded in real-world conditions, the team identified 309 total clashes, 198 of which—64%—were only visible because of laser scanning combined with structural modeling. These conflicts would not have been detected using drawings alone.

By resolving those issues virtually, the team was able to:

- Avoid 45+ RFIs and the associated construction delays

- Prevent significant field rework and trade chargebacks

- Reduce site walks, engineering back-and-forth, and reactive coordination

- Protect the project schedule by keeping conflict resolution out of the field

Based on weighted clash severity and GC feedback, the avoided rework and chargebacks represented approximately $450,000 in cost avoidance, against an OAR engagement cost of $50,000—an 8× return on investment.

The outcome wasn’t a perfectly “digital” project. It was a more predictable one: a buildable, coordinated plan, clearer accountability across trades, faster installations, and a shared record of decisions that carried through to closeout.

The case study resonated because it reflected challenges contractors see every day—and showed that reducing risk doesn’t require rebuilding processes from scratch. It requires replacing unverified assumptions early, so downstream decisions are based on reality instead of guesswork.

For mid-size contractors, the advantage is partnership—not building everything in-house

Large national contractors can afford dedicated internal VDC and BIM teams. Many regional and mid-size contractors cannot—and shouldn’t need to.

What TechCon highlighted is the opportunity to adopt proven workflows through the right partners, without carrying long-term overhead.

The objective isn’t ownership of every tool.

The objective is reliable outcomes.

Practical steps contractors can take now

For teams looking to reduce surprises and improve coordination:

- Start with verified existing conditions

Especially in renovations, accuracy upfront eliminates preventable RFIs and rework.

- Coordinate before issues reach the field

Early alignment is where conflicts are cheapest to resolve.

- Treat the workflow as a deliverable

Consistency creates clarity. Clarity accelerates decisions.

Final thought: certainty is the advantage that compounds

ABC TechCon 2026 reinforced a simple truth: Contractors don’t win by having more tools or trying to keep apace with the latest technology. They win by having fewer unknowns and building more efficiently and faster.

Certainty protects schedules, reduces rework, and strengthens outcomes for owners and project teams alike.

If you have an upcoming project and need to understand how existing conditions, coordination, and early decisions could impact risk, schedule, or cost, let’s talk.