Table of Contents

Bad data in construction is not a minor annoyance. It’s a billion-dollar drag on schedules, shutdowns, and margins. In 2021, Autodesk and FMI reported a staggering number: bad data in construction costs the global industry $1.8 trillion every year.

Behind that number sits something deeper—avoidable rework, schedule slips, misalignment between teams, and plans that become unconstructable because they do not match field conditions. As we enter 2026, tolerance for inaccurate, incomplete, or outdated information is disappearing fast. A simple laser scan and correctly formatted data can eliminate this risk.

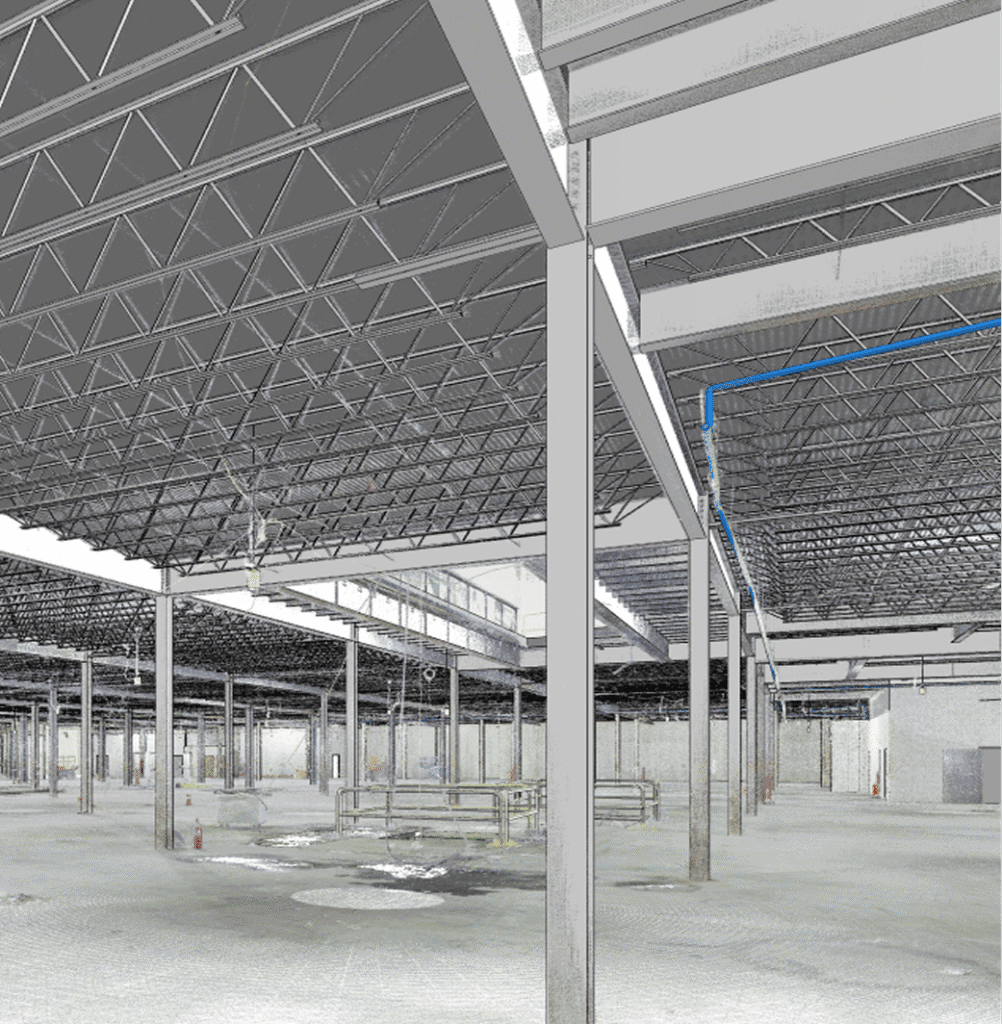

Today, digital transformation isn’t a competitive edge. It’s risk reduction. It’s operational efficiency. It’s how industrial owners prevent shutdown overruns and eliminate uncertainty before fabrication begins. And among all digital tools, reality capture—LiDAR, 3D scanning, and accurate 3D modeling of existing conditions from point-cloud data—delivers the clearest path to accurate decisions.

This article explains why bad data in construction remains one of construction’s most expensive (and avoidable) problems and how reality capture is reshaping expectations in 2026.

What “Bad Data” Really Means on a Jobsite

Bad data in construction goes far beyond incorrect numbers. It includes:

- Wrong or inconsistent field measurements

- Outdated drawings, as-builts, and models

- Missing documentation

- Conflicting information between teams

- Manual measurement errors

- Site conditions no one has fully verified

When field truth is missing, misalignment escalates.

Plans don’t match the structure. Fabrication stalls. Installations fail inspection. Crews redo work. Costs climb. Schedules slip.

And it costs far more than most teams realize.

The $1.8 Trillion Problem: How Bad Data In Construction Turns Into Real Losses

Rework

Up to 14% of rework stems directly from bad or missing information. In industrial environments, that often means lost shutdown windows, missed production targets, and costly labor resets.

Lost Productivity

Bad data slows everyone down:

- Crews stop work waiting for answers.

- Engineers re-measure what should have been verified.

- Fabricators halt production until discrepancies are resolved.

Small data gaps compound into major delays.

Downtime & Coordination Breakdowns

Installers show up to conditions that don’t match the drawings.

Equipment doesn’t fit.

Layouts shift mid-install.

Idle labor becomes unavoidable.

Bad data is expensive because it multiplies. It affects decisions, schedules, and outcomes.

Why Data Accuracy Is Increasingly Expected in 2026

Several trends are pushing owners and project teams to expect better site data:

1. Reality Capture Maturity

Modern LiDAR scanners, drones, and mobile mapping tools deliver sub-inch accuracy in hours, not days. Dense point clouds plug directly into BIM, enabling verified as-builts and confident planning.

2. AI-Driven Processing

AI rapidly classifies point clouds, detects clashes, and flags anomalies.

What once took weeks now takes hours.

3. Digital Twin Requirements

Industrial owners increasingly require verified as-builts and digital twins to support operations, maintenance, and future retrofits. Reality capture is the foundation that makes this possible.

4. Precision as Cost Control

With rising labor costs, supply volatility, and shrinking shutdown windows, precision is one of the strongest cost-saving levers available.

Owners do not want guesswork.

Reality capture delivers the accuracy modern projects demand.

Reality Capture: The Most Direct Solution to Bad Data

Reality capture replaces assumptions with verified, measurable field truth.

Millimeter Accuracy

LiDAR and 3D scanning create a precise digital record of existing conditions—no estimating and no outdated drawings.

Rapid Capture, Rapid Decisions

What once required full-day site visits now takes under an hour, enabling faster, more confident decisions.

Better Coordination

When architects, engineers, fabricators, and contractors share the same point cloud or as-built model, alignment improves and rework drops sharply.

Long-Term Value

Reality capture supports operations, maintenance, retrofits, expansions, and asset planning for years.

The result? Less risk. Fewer surprises. More predictable costs.

How OAR Cuts the Cost of Bad Data for Industrial Owners

At OAR, we give owners the one thing traditional workflows can’t guarantee: certainty in the field.

We deliver:

- High-accuracy LiDAR and 3D scanning

- Complete digital documentation of existing conditions

- BIM-ready point clouds and as-built Revit models

- Reality-based verification to align designers, fabricators, and contractors

For heavily regulated, high-downtime industrial sites, accurate data prevents costly shutdown overruns, protects budgets, and improves planning.

For engineering consultants and contractors, we bridge capability gaps and remove bottlenecks.

Bad data in construction is costly.

Reality capture is the remedy.

Conclusion: 2026 Is the Year to End Guesswork

The industry can no longer absorb the hidden cost of inaccurate information. As digital workflows mature, owners who invest in verified site data gain faster schedules, fewer changes, and more predictable budgets.

If you’re ready to eliminate rework, reduce risk, and build with confidence, OAR can help.

Connect with our team to see how reality capture improves your next project.